1e. Introduction

ЭI became interested in solar water heaters more than 5 years ago. Selective coating attracted attention - the characteristics are close to ideal. And at the same time – single-layer glass thermal insulation... Single-layer windows have not been used for a long time even in villages. But here multilayer glass is not suitable - the complication of the structure and a significant weighting ... Replacing glass with plastic solves a number of problems. The question arose: is it still possible to improve the characteristics of such water heaters due to more advanced thermal insulation? And: how much can heat loss be reduced by the radiation of a conventional (non-selective) coating by using multilayer screens? Is selective coverage really necessary? I decided to test some ideas experimentally on a model (warm-up mode) with a non-selective coating. Here it is, in the photo. No, I was not going to use it for practical purposes - there is nowhere ... Just measure the characteristics. And its advantage is the ease of alterations, the ability to test different constructs.

Neighbors in the garage approved. They especially liked how it cheerfully let out a stream of steam in late autumn, at a temperature of about 0 degrees.

The result: some designs showed a fairly high useful power. Some did not live up to expectations. As the analysis later showed, and could not be effective. I will tell you in more detail later, but the main conclusion is that a non-selective coating can be used at least at temperatures down to zero degrees. With selective coating, the characteristics are better, but it's more expensive...

But the most important conclusion that I quickly made for myself is that not everything is so simple.... In multilayer transparent thermal insulation, rather complex heat transfer mechanisms operate. Intuitively, "by poking" it is impossible to quickly find the right solution. Mathematical modeling allows you to significantly shorten this path, allows you to start modeling from a point that is quite close to the optimum.

The characteristics of the insulation constructs used in the model were verified by calculations. The results of the calculations showed good convergence with the results of the experiments. This gave grounds for confidence in the calculations of other isolation options.

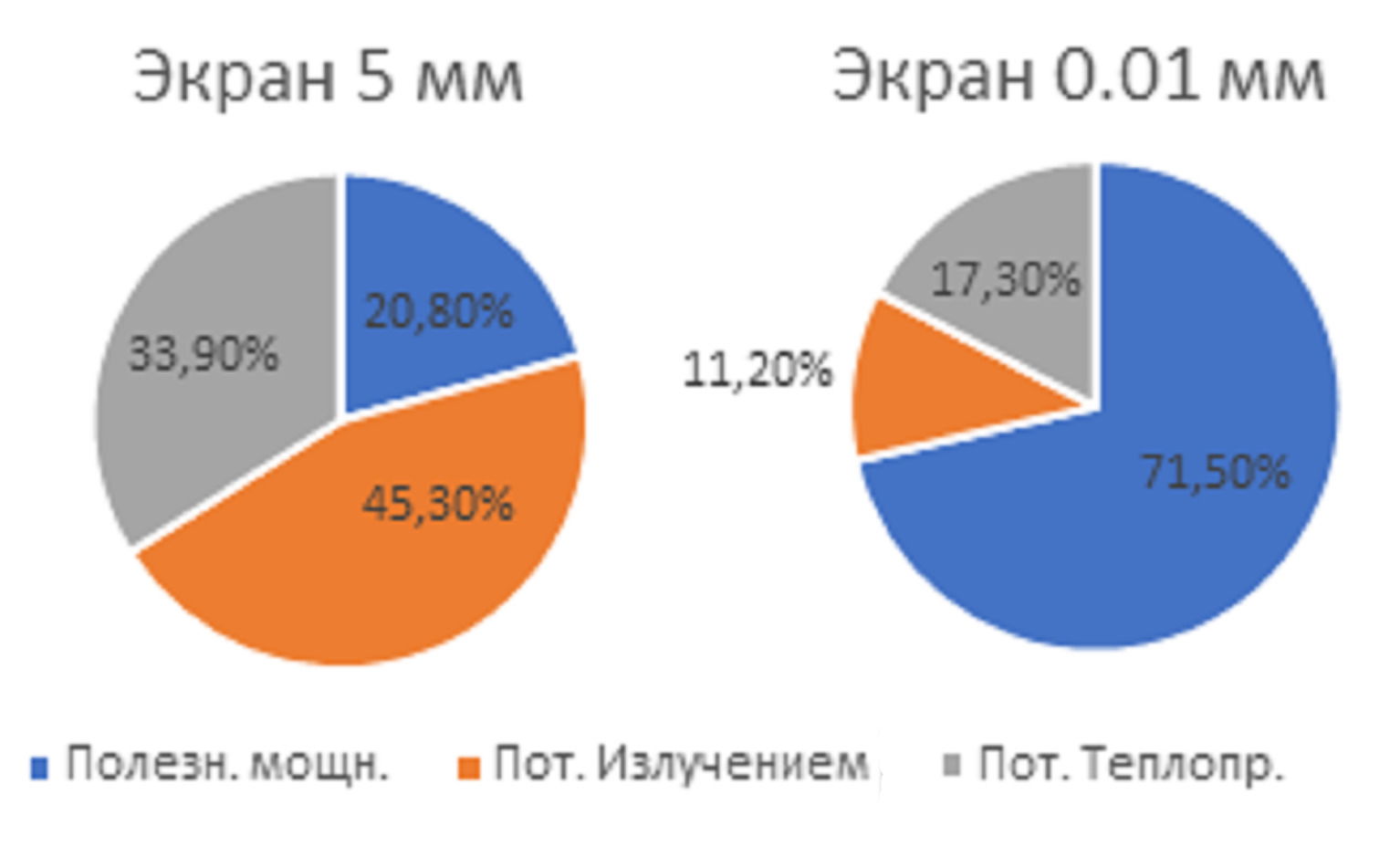

As an example, consider the calculated characteristics of two variants of the simplest single-layer insulation. For calculations, the boundary thicknesses of the screens are taken:

- 5 mm - the maximum thickness of the glass used to insulate solar water heaters; the calculations take the spectral characteristics of polycarbonate (close to glass);

- 0.01 mm – minimum thickness of polycarbonate film available on the market.

For the calculation it is also accepted:

- solar radiation power – 1000 W/m2, including = UV – 100, = visible – 450, = IR SV – 450;

- absorber/air temperature – 100/0 °С;

- koef. absorber absorption - 0.95/0.03;

- air gap thickness – 40 mm.

As shown in the diagram, with a screen thickness of 5 mm, the efficiency in this mode is reduced to about 21%. The main part of heat loss (45%) falls on radiation - despite the reduced temperature, such a screen is a more powerful emitter of thermal energy than an absorber (emissivity 0.9 and 0.03). Reducing the thickness of the screen dramatically increases the efficiency to about 72%.

In both of these options, the strength characteristics are not balanced with their required values. For example, for a glass sheet, resistance to hail is provided at a thickness of about 5 mm (due to its high fragility). For polycarbonate, such a thickness is clearly excessive. Honeycomb polycarbonate panels are considered to be resistant to hail with shell thicknesses of about 0.5-0.7 mm. It can be assumed that more elastic plastic structures will be able to withstand hail effects with a smaller thickness of the shells. However, these assumptions certainly require confirmation by experiments. Thus, in the development of solar-active (transparent) thermal insulation, one of the main tasks is to balance its strength and thermophysical characteristics. In other words, achieving maximum thermophysical characteristics at a given strength.

Looking ahead, I can say that the most effective of the known solar water heaters with vacuum tubes were also far from perfect....

I'm going to consider, first of all, water heaters from honeycomb panels. This is the simplest and quite effective design, which is easy to manufacture even in garage conditions. This is the first step, here I will try to explain everything without ceasing, I will answer questions. But there are at least second and third steps... I haven't decided here yet. I hope for understanding.